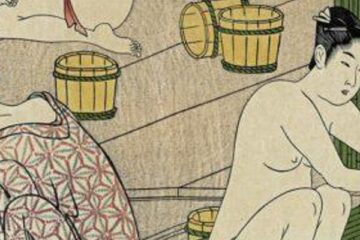

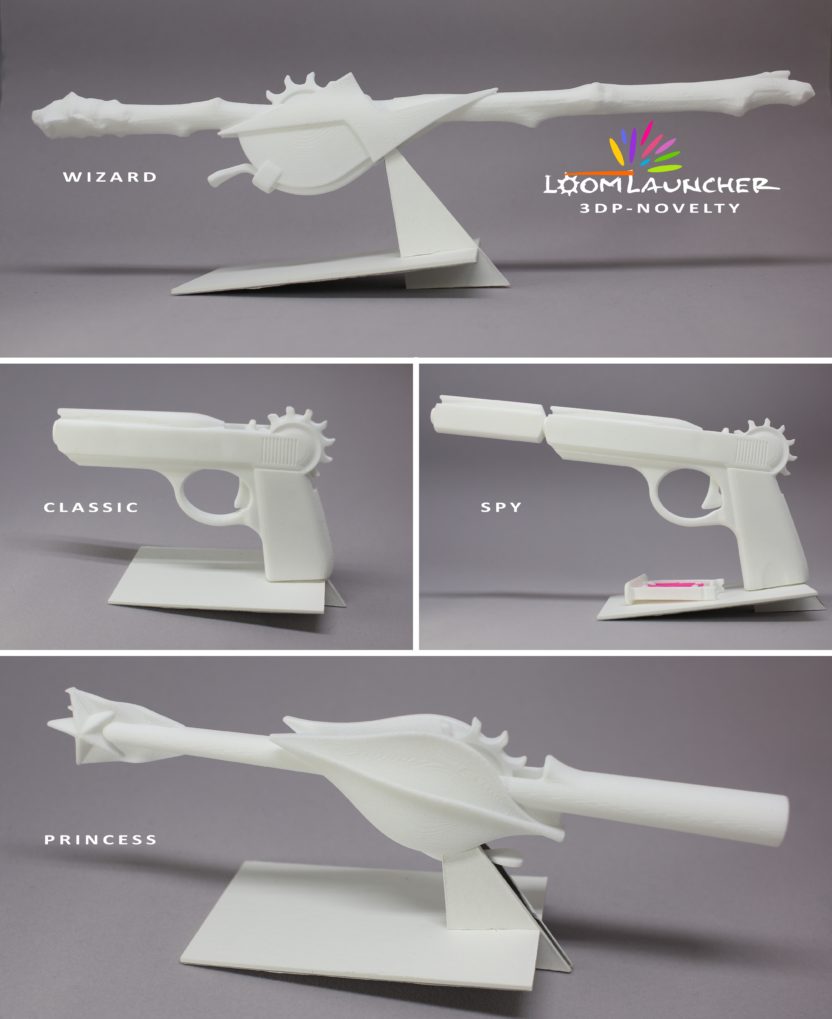

3D printing presents a more sustainable proposition and I’ve designed a product to test it. Loom Launcher is one of the first 3D printed products that can be custom-made on-demand and has been designed to be cost competitive compared to similar products made using the old industrial model of mass-producing and distributing products. It’s a virtual product from conception right through to production and entirely managed by digital systems up until it’s prepared for delivery.

In my article ‘Printing 3D Guns – Bringing 3D Printing to The Forefront’ I talk about how 3D printing is already changing the way products and components are made in many industries from healthcare to car manufacturing. Interestingly, automotive giant Ford, the legacy of Henry Ford who is considered the forefather of mass production, is now using 3D printing in the design of cars at its Technical Centre in the UK – a stark contrast to the methods of mass production his name has become synonymous with.

On-demand manufacturing decreases the lead time between concept and product and reduces the upfront costs for the designer or manufacturers. Plus, as products are only produced just in time for when a customer places an order there are minimal up-front risks. Dubbed as a “personal factory”, the technology is democratising digital life and this hasn’t escaped the attention of online marketplaces like Amazon. The e-commerce giant is said to be hoping to cash in on the advances in 3D printing technology to bring customers whatever they want as soon as they want it. According to a patent application Amazon have filed in the US they’re hoping to release trucks with on-board 3D printers that will take online orders and create the ordered product either on the way to or at the customer’s door! This could save them millions of dollars in storage facilities and, of course, stock.

In the eyes of the masses 3D printing is a very complex technology that is only accessible to computer geeks and product designers. Creating a three dimensional design? Getting access to a 3D printer? Choosing the right printing material? It’s actually far easier than it may appear. Even those with little to no experience in design or technology can now start printing objects in no time and 3D printing is more accessible than ever before.

The Loom Launcher is testament to this. It’s a 3D printed toy for kids and for the young-at-heart – but it’s also more than this. It’s a deliberate design attempt to make 3D printing more accessible to consumers and was done so by leveraging other digital democracies like crowdfunding and social networks.

3D printing and crowdfunding have a lot in common – both are innovations that are changing the way we look at the marketplace and both are vehicles for entrepreneurial freedom. They have bridged the gap between what people only ever dreamt of achieving and what they can now achieve – and all from the comfort of the cloud on their own computer.

So it’s no wonder that crowdfunding sites like Kickstarter are behind lots of 3D printing projects – read my recent article ‘My story – of Passion, Printing and Prototypes’ where I share my journey going from frustrated designer to Kickstarter and crowdfunding advocate.

Advances in 3D printing have made the technology accessible to anyone who wants to turn an idea into something tangible, translating their vision into something that they can touch, play with and even sell. On-demand manufacturing is set to make production more sustainable. While we could expect to see more products created, the result is just the opposite as it creates a marketplace where products are produced to order – slashing lead times, with less risk and cost but with more choice and freedom for the consumer, with only products that are in demand produced to fulfill actual needs as they arise.