Blog

Thought Musings, and News.

A Water Heater that Doubles AI Server Efficiency gets a Patent.

We’re mixing computer data with hot water for a more sustainable future.

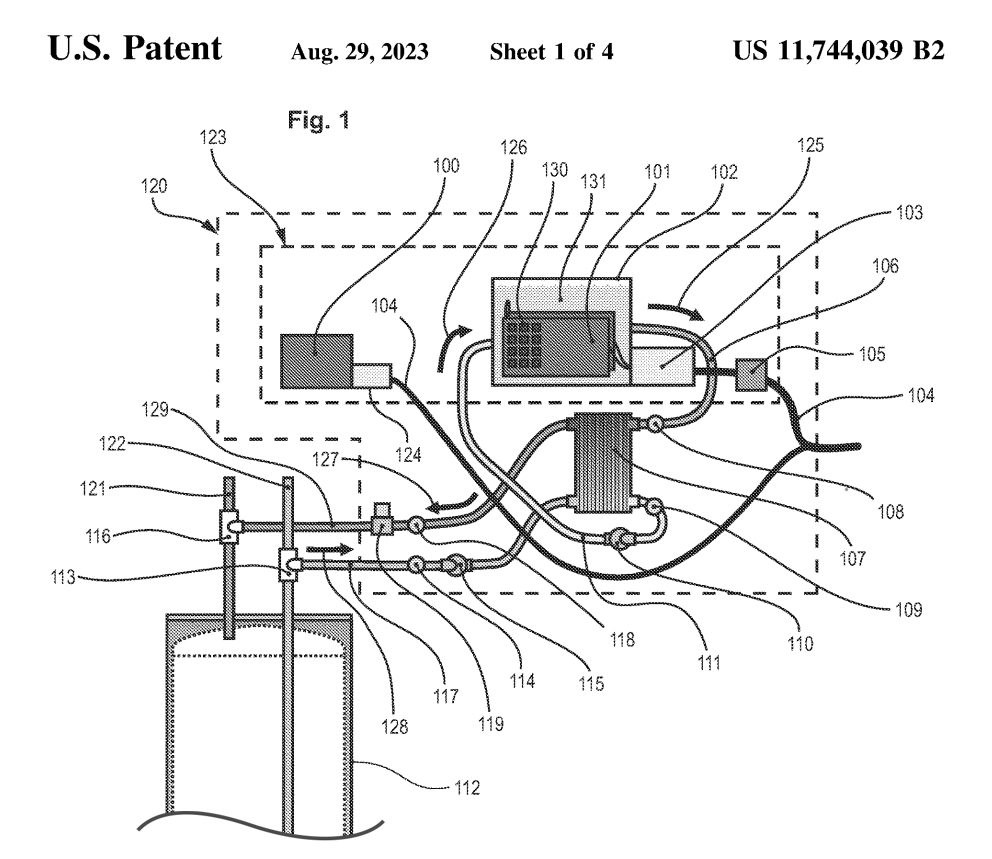

If you don’t think of waste as a finished product, our new patent explains how that’s about to change. JDi Design inc. has invented a device that recycles waste heat by pumping hot water straight into your water tank, ready for your morning shower. We call it the HRU (Heat Recycling Unit).

The invention is a non-condensing heat pump that takes waste heat from cloud computing and recycles it to heat residential and commercial hot water. The HRU is a solution to the growing challenge of how to reduce our ecological footprint without making quality-of-life sacrifices.

While the internet genie is out of the bottle, it’s expanding, spawning more and more warehouses full of computer servers. These are data centers, the digital nerve clusters that connect the world’s minds and ideas in a vast web of information.

The biggest part of a data center’s operating costs is spent converting electricity into data and dumping heat. At the same time, people all over the world are spending more money on electricity and paying for heat. The need for electricity is increasing, and it’s ramping up at the same time governments are attempting to decarbonize and electrify our economy.

Our 21st-century society depends on data and electricity as much as we’ve rely on in-house plumbing. These are essential services. We shouldn’t be wasting either, nor should we sacrifice one for another. Who wants to give up a hot shower so data centers can have more power?

By collocating our HRU servers with a demand for heat, we can double the efficiency of electricity and, in some scenarios, offset CO2 production with no additional electricity demand.

JDi’s patent describes how we improve electricity efficiency and create second-order benefits, like reducing your environmental footprint CO2 emissions, and freeing up electricity for high-tech data services. Our HRU is enabling a smart hot water network for modern cities to transition from a growth-based hydrocarbon economy to an advanced electrified one without making a quality-of-life sacrifice.

We aim to store energy in your hot water tank like a distributed energy battery. What’s new is a network of computer servers working in the background while we help coordinate and balance renewable energy generation with peak grid demand. The HRU can also free up electricity for a Proof of Work blockchain and growing generative AI networks without the need to produce more electricity.

The hot water at your faucet doesn’t change. It just gets better.

If you’ve read this far, you may wonder if this works and why it’s never been done before.

The bottom line. Computers convert electricity into heat when they process data. The sheer scale of this cooling problem has ignited a staggering number of innovative methods to cool digital processors.

Existing cooling methods are handicapped when recycling waste heat. They’re optimized for cooling and cannot manage a deteriorating temperature gradient when moving heat from one location to another.

JDi’s patented innovation that makes the HRU’s heat recycling possible uses two fluid circuits, and algorithmic control of a second fluid circuit to manage heating and a cooling system. By intentionally regulating the flow rate of the second fluid circuit, heat from digital processing is extracted at a constant rate, then relocated and delivered at a specific temperature to your appliance. The most obvious application is your hot water tank.

This is not just great in theory or a good idea on paper. To use computing tech jargon, Moore’s law just got a power boost that doubles the efficiency of cloud-based digital processing.

Our HRU is part of a growing data server network that’s been recycling waste heat in the wild for over three years. Hundreds of people are using hot water heated with HRU’s recycled energy, and it’s catching on as we grow.

One of the most appealing aspects of recycling heat from waste electricity with our HRU is it generates revenue, creating an economic incentive to make the change, recycle and transition to a sustainable future.

Please follow along on Linkedin and join me on this journey to change the way billions of us heat the water we use every day.

© 2019 JDi Design inc. All rights Reserved.